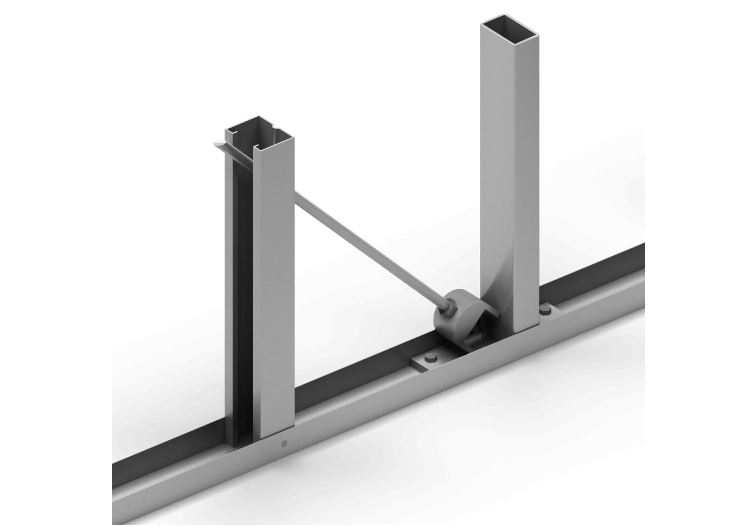

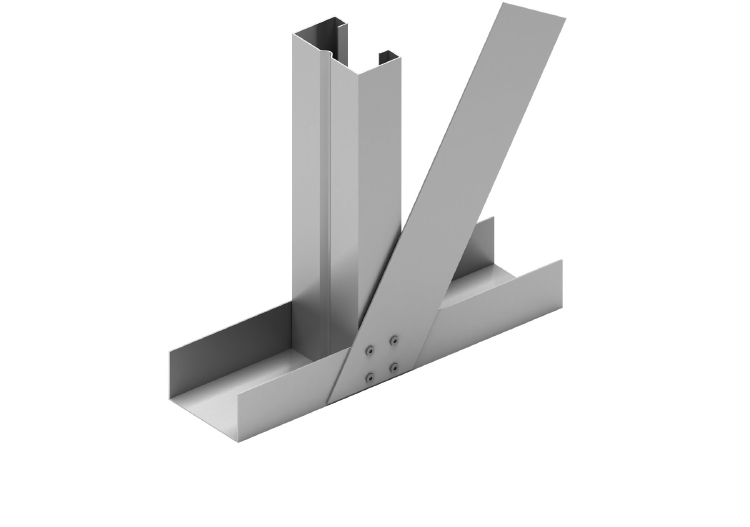

Galvanised 2D volumetric structural steel frames for multi-storey buildings using Sigmat patented technologies.

THE SIGMAT LGSF SYSTEM

2D Volumetric Construction

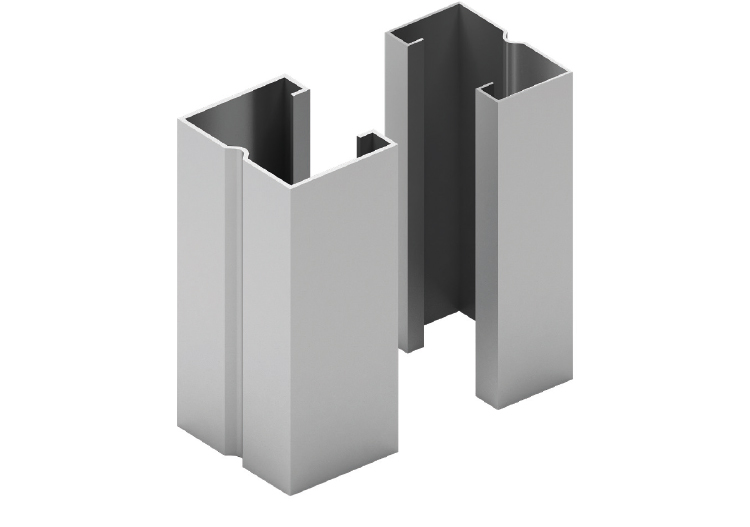

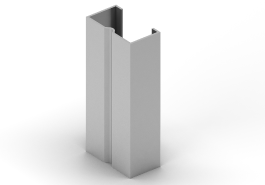

Structural steel frames designed "in-house" using patented technology and industry leading solutions. Sigmat primary stud component up to 17.8% stronger than non-patented alternatives.

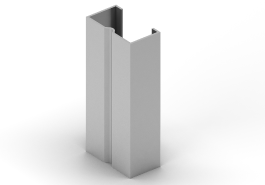

All Sigmat profile sections are manufactured using hot dipped galvanised steel to (BSEN 10143:2006) in grades from S280 and S450, as required. They have a Z275 coating and are supplied self-finished.

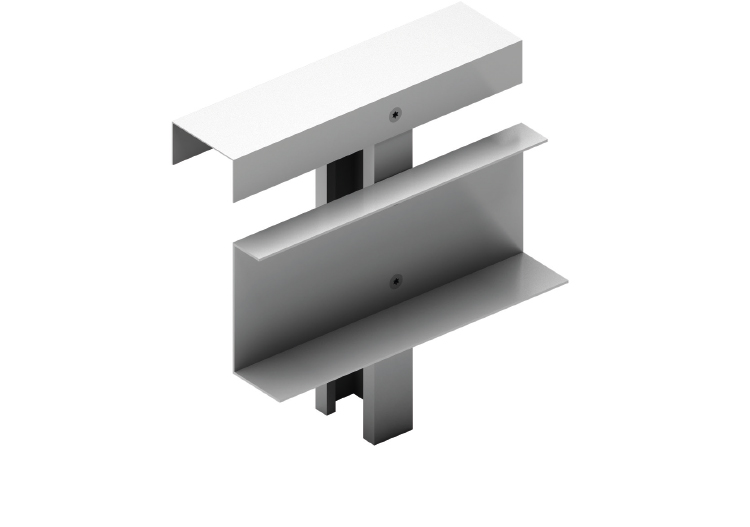

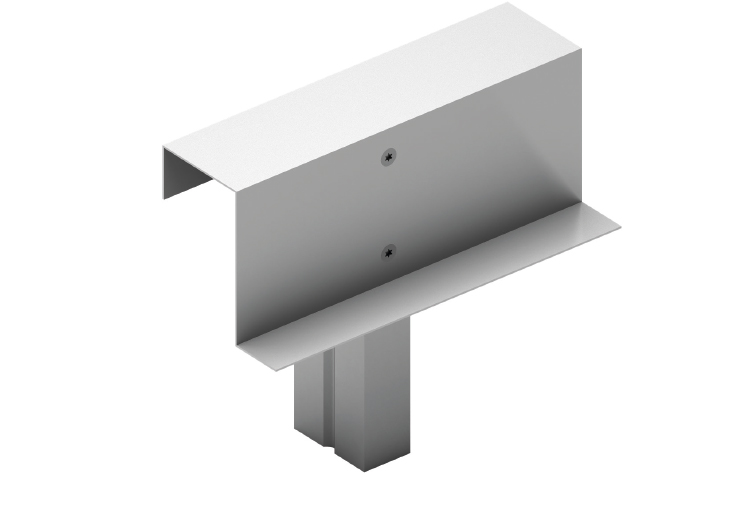

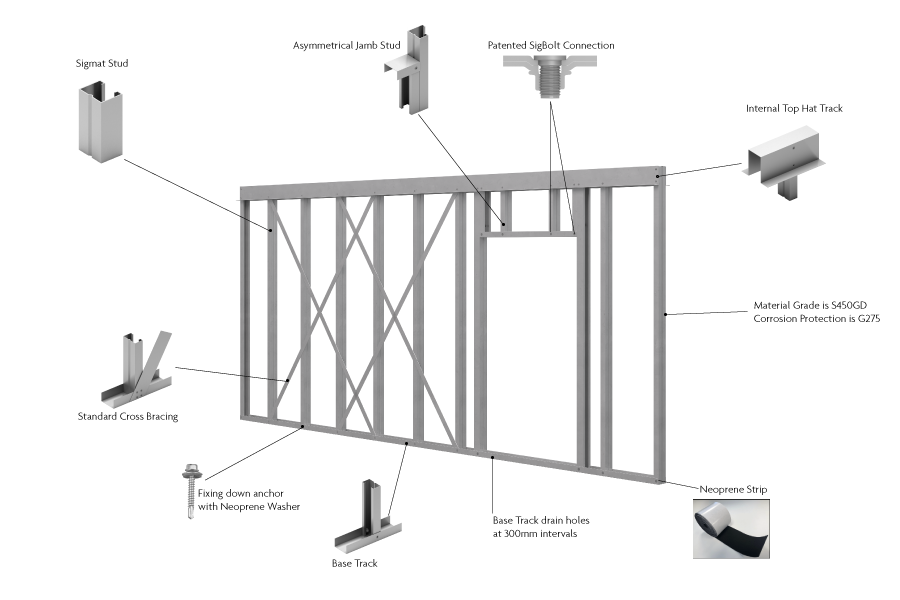

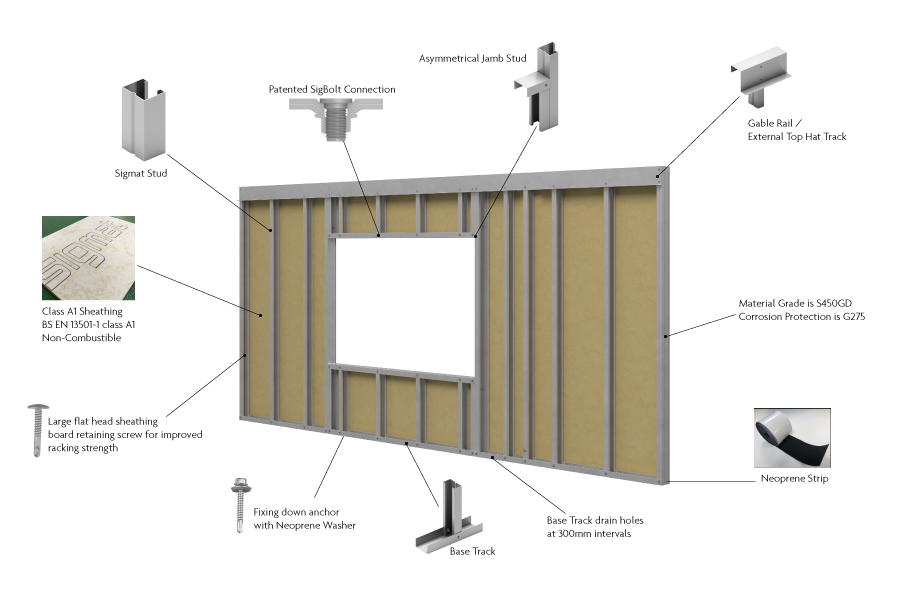

Key Sigmat component elements summarised below:

Typical Internal Wall Construction Features

Components in more detail below, click for more detail

Typical External Wall Construction Features

Components in more detail below, click for more detail

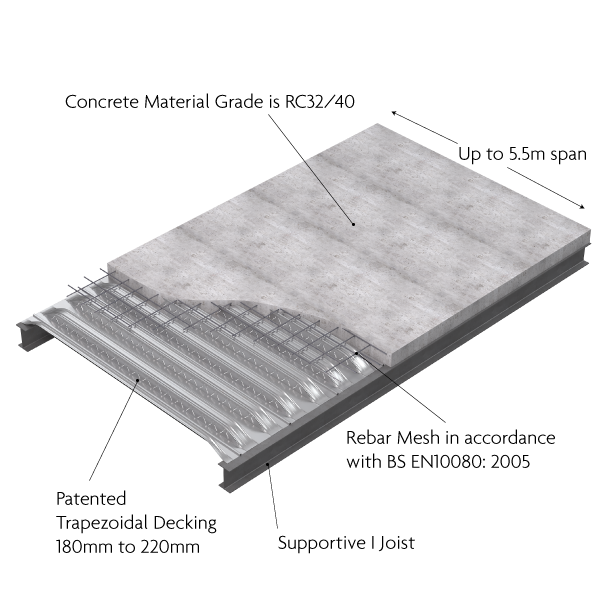

Typical Floor Construction Solutions

Choice of three different floor construction options

Components in more detail below, click for more detail

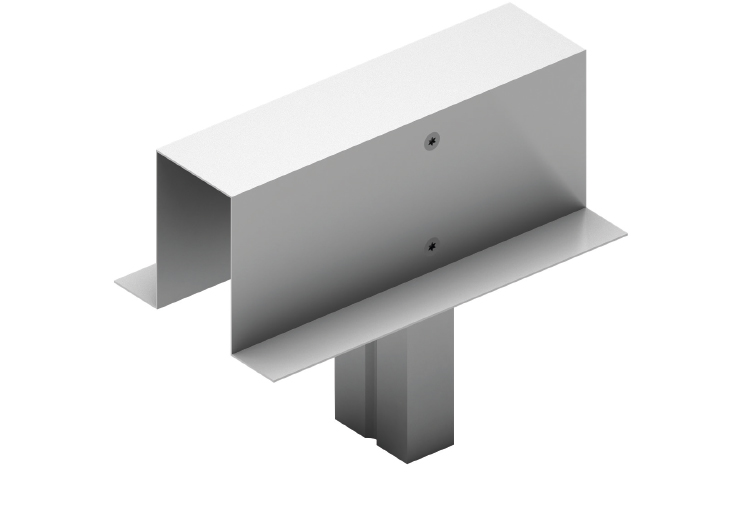

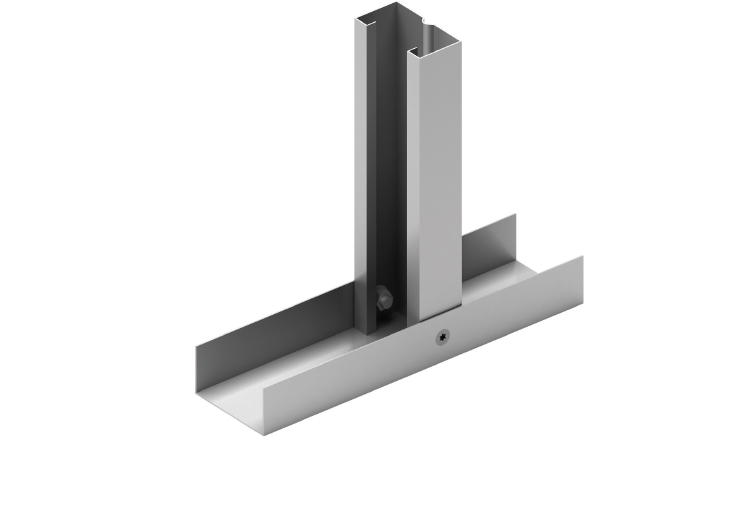

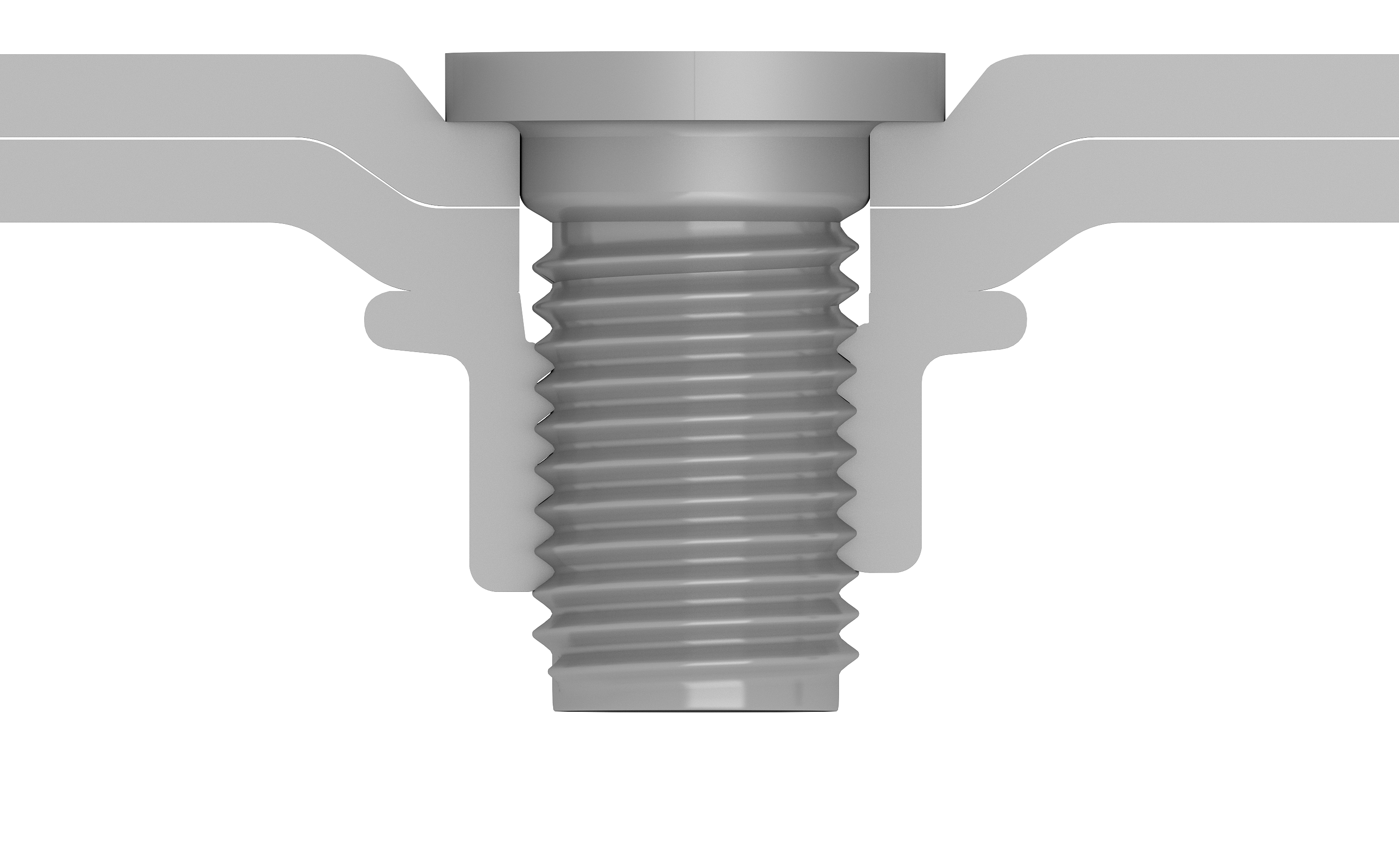

Patented Connections

Components in more detail, click for more detail