A complete solution from initial design through to on-site installation of LGSF load-bearing and SFS non load-bearing panelised frames.

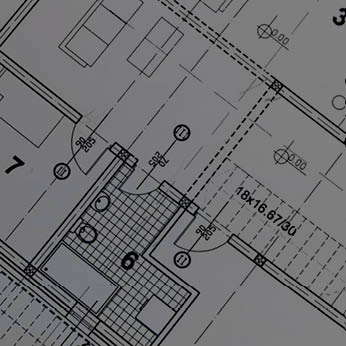

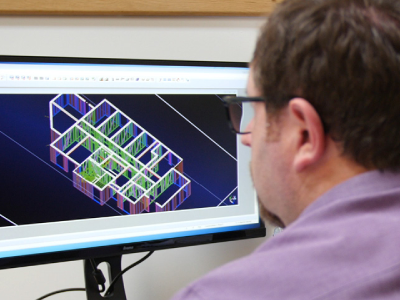

Design

Our in-house building Designers and Structural Engineers utilise Tekla BIM software to design the appropriate and most efficient building superstructures that are EC3 compliant. Each solution is rendered via Tekla into a 3D, BIM ready model.

Manufacture

Once the design is approved, design specifications from Tekla are automatically transferred directly to our cold rollforming mills, ensuring absolute accuracy from design to manufacturing of every cold rolled component section and profile. Hot rolled fabricated panel strengthening components are manufactured in parallel ready for final assembly. Each component is barcoded and moves to the panel assembly area where it is assembled into finished panels.

Assemble

Cold rolled components combine with fabricated HRS sections and are assembled in-house into storey height panels, typically 3m to 8m in size. External panels receive an A1 fire-rated 12mm Y-wall sheathing board to provide water and fire protection. Depending on client requirements, additional insultation and support channels are installed at this time. Each panel receives a unique panel assembly number ready for its timed slot in the on-site install process.

Install

Careful planning and coordination ensures that the Sigmat programme dovetails closely with the full project build. Our on-site teams have experience on more than 300 schemes and will work closely to ensure project prelim savings offer the greatest advantage in cost and build time.